In the highly competitive landscape of modern manufacturing, the efficiency of a production line is often defined by the longevity and reliability of its tooling. Stamping dies operate at the heart of mass production, subjected to millions of cycles of immense pressure, friction, and thermal stress. For engineers and procurement managers, extending the service life of stamping die components is not merely a cost-saving measure; it is a critical strategy for ensuring consistent part quality, reducing unplanned downtime, and maintaining a competitive edge in a volatile market.

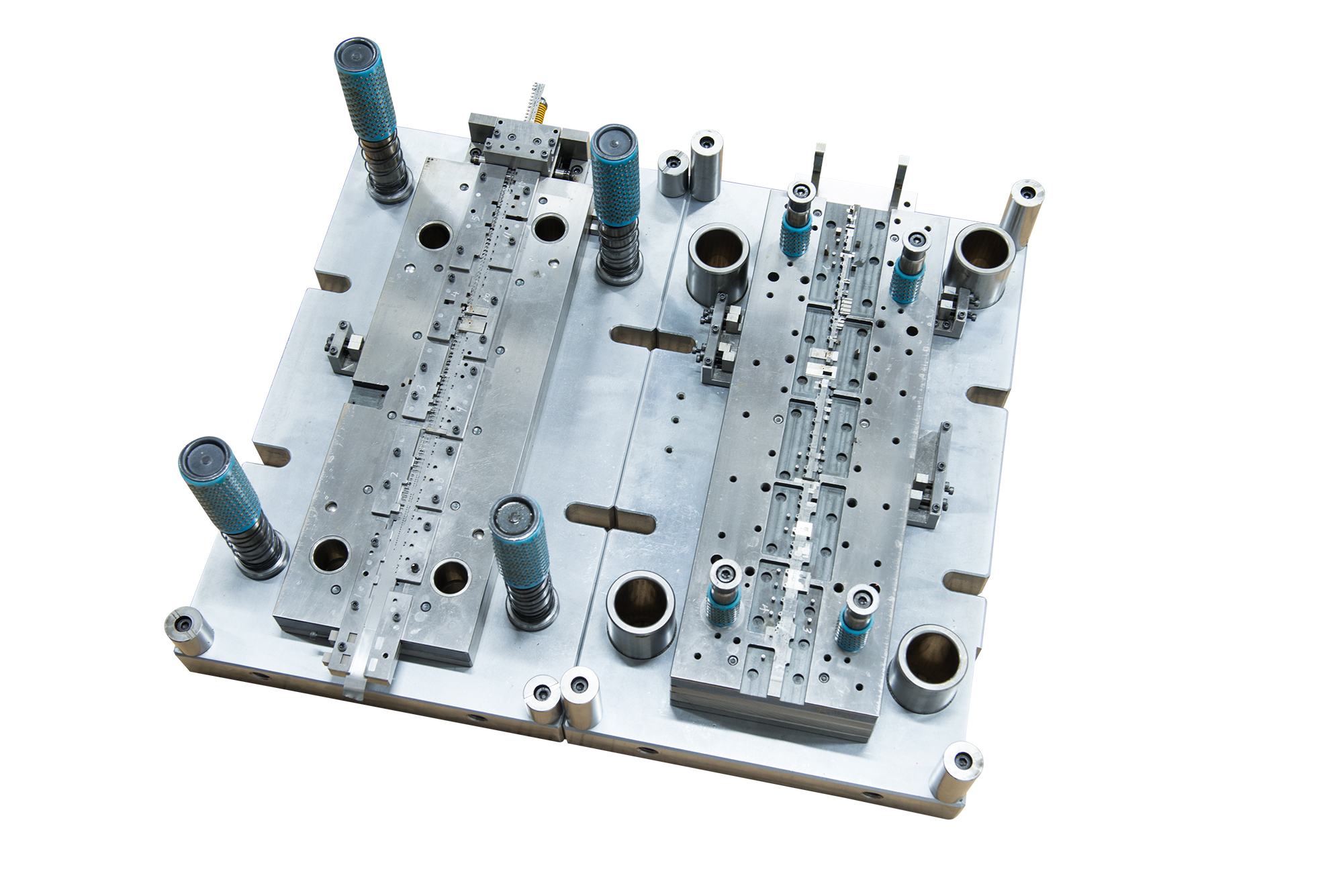

To understand how to prolong tool life, one must first appreciate the rigorous demands placed on the die. The fundamental principle of a stamping die involves the transformation of flat metal sheets into complex geometries through shearing, punching, or forming. This process relies entirely on the precise interaction between the punch and the matrix.

A robust design philosophy must prioritize structural integrity. The die set must possess sufficient rigidity to resist deflection under heavy loads. Even a micron-level misalignment can lead to uneven wear patterns, significantly reducing the lifespan of the tool. Modern design requirements emphasize optimized clearance—the gap between the punch and the die. This must be calculated with extreme precision based on material thickness and shear strength to prevent premature burr formation and edge chipping.

Before delving into advanced manufacturing solutions, several operational practices are standard for maintaining tool health:

Predictive Maintenance: Implementing a schedule for sharpening before the cutting edge degrades excessively minimizes the amount of material that needs to be removed during regrinding.

Vibration Control: Utilizing high-rigidity guide pillars helps ensure that precision mold parts remain perfectly centered during high-speed strokes, preventing lateral movement.

Lubrication Management: Using the correct viscosity of lubricant reduces the thermal shock on the cutting edges.

However, while maintenance is vital, the ultimate ceiling of a tool's performance is determined at the manufacturing stage. This is where the choice of manufacturing partner becomes the deciding factor.

The gap between a standard tool and a high-performance tool often lies in the invisible details of manufacturing. At HONGYU MOULD LIMITED, the philosophy is that tool life is engineered, not accidental. By integrating superior raw materials with distinct processing technologies, we address the root causes of tool failure: fatigue, abrasion, and adhesion.

The foundation of durability is the substrate. Standard tool steels often fail to meet the demands of modern high-speed stamping. HONGYU MOULD LIMITED has established a robust supply chain to source premium tungsten carbide materials and high-vanadium powder metallurgy steels.

Unlike generic suppliers who may struggle with material consistency, we ensure that the carbide grades we utilize offer the optimal balance of transverse rupture strength and fracture toughness. This material stability is crucial for preventing the micro-fractures that often occur during high-impact stamping operations.

Precision is the enemy of friction. The smoother and more accurate the component, the less heat and wear it generates. HONGYU MOULD LIMITED employs a suite of high-precision manufacturing processes, including Mirror Optical Profile Grinding (PG) with tolerance ±0.002mm.

Surface finish plays a decisive role in preventing "galling"—the phenomenon where workpiece material welds itself to the tool surface due to heat and pressure.

Our engineering team focuses heavily on surface morphology. Through specialized polishing techniques, we achieve mirror-like finishes with extremely low Ra (Roughness Average) values. This ultra-smooth surface reduces the coefficient of friction, allowing the strip material to flow seamlessly. This not only protects the tool but also enhances the aesthetic quality of the final stamped product, a critical requirement for consumer electronics and automotive parts.

To provide an ultimate shield against abrasive wear, HONGYU MOULD LIMITED integrates advanced surface treatments. Depending on the application, we apply PVD coatings such as TiAlN, Tin, Ticn, Alcrona, or DLC.

These coatings provide a surface hardness that far exceeds that of the base metal while offering excellent thermal stability. In applications involving stainless steel or high-strength alloys, these coatings act as a thermal barrier, preserving the hardness of the underlying component even under continuous thermal stress.

Extending the service life of your tooling is a multi-faceted challenge that requires a synergy between smart maintenance and elite manufacturing. By leveraging the advanced capabilities of HONGYU MOULD LIMITED—from the sourcing of high-grade raw materials to the application of micron-level precision grinding—manufacturers can achieve significantly higher output with fewer tool changes.

In a global market where raw material costs are fluctuating, investing in high-quality tooling is the most effective way to insulate your production line from instability. A durable tool is not just a component; it is an assurance of continuous, profitable production.