Injection Molding: Revolutionizing Manufacturing and Enhancing Daily Life

Sep 23, 2024

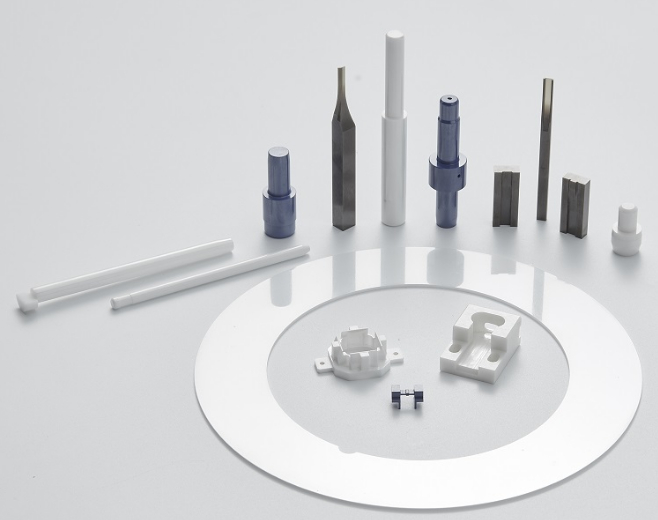

Injection molding is a vital manufacturing technique that has transformed various industries by enabling the mass production of intricate plastic components. With its precision, efficiency, and versatility, injection molding has become an indispensable process in the production of plastic mold parts. This article will introduce the production process of injection mold components and explore their applications in different scenarios, highlighting how they significantly impact our daily lives.

1. The Injection Molding Process:

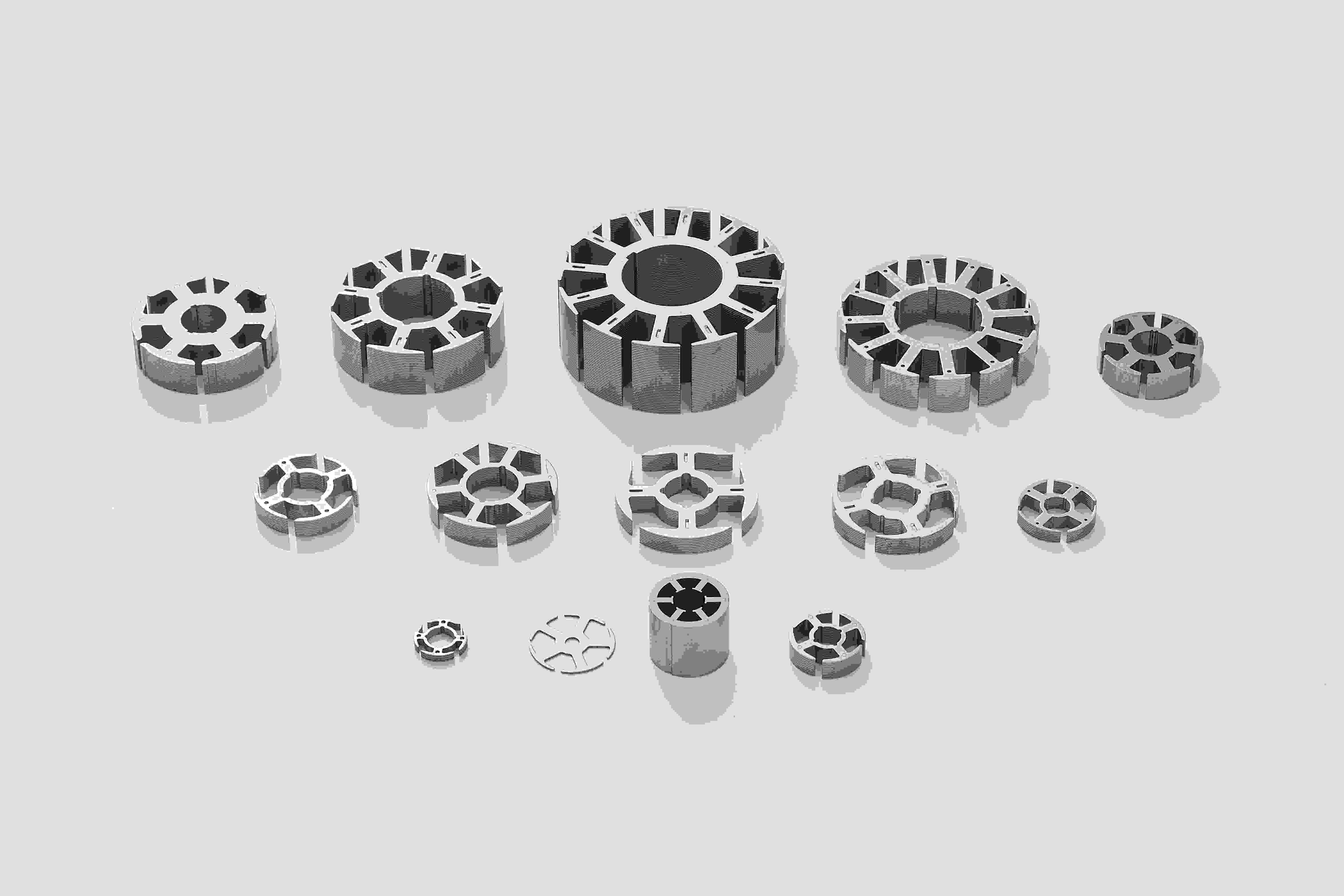

Injection molding is the creation of a mold cavity into which molten plastic material is injected under high pressure. The process can be broadly divided into the following steps:

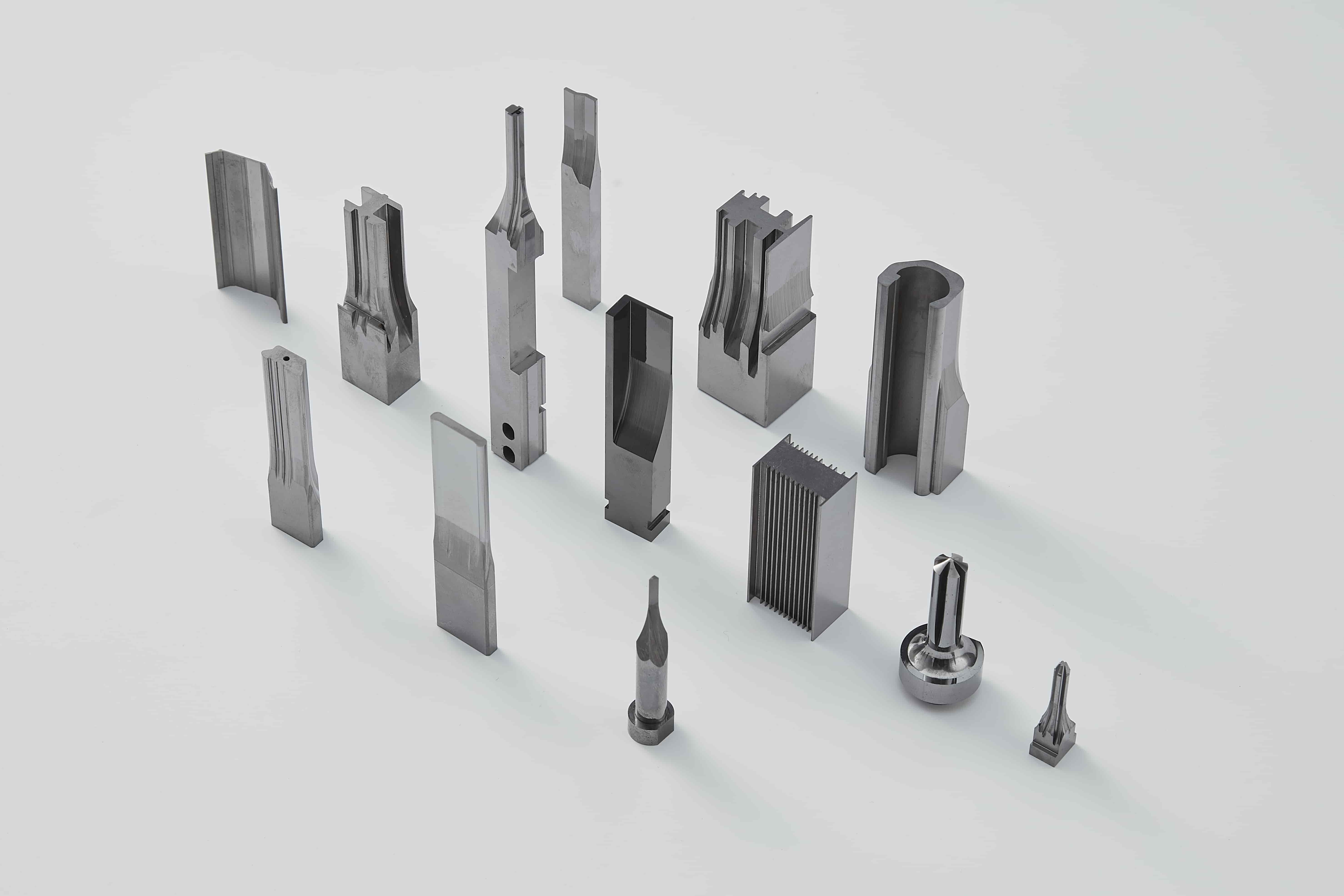

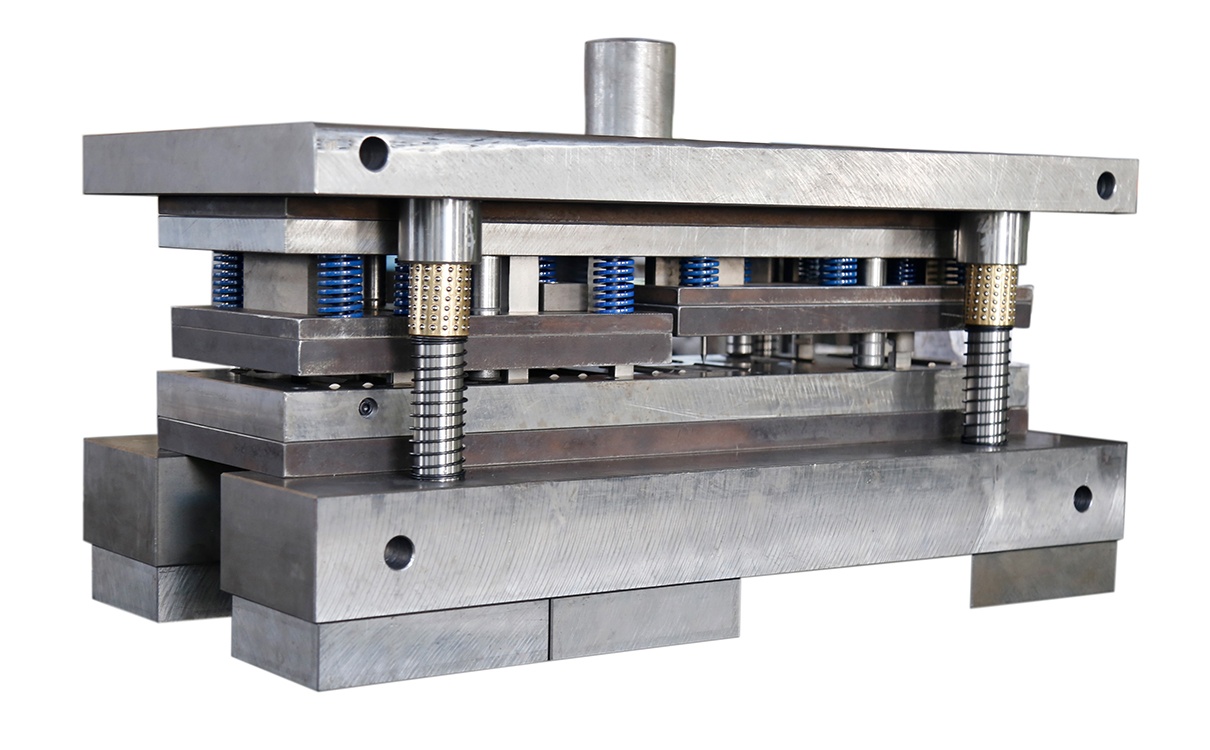

a.Mold Design and Development: Skilled engineers and designers use advanced software to create detailed mold designs, considering factors such as part geometry, material selection, and ejection mechanisms.

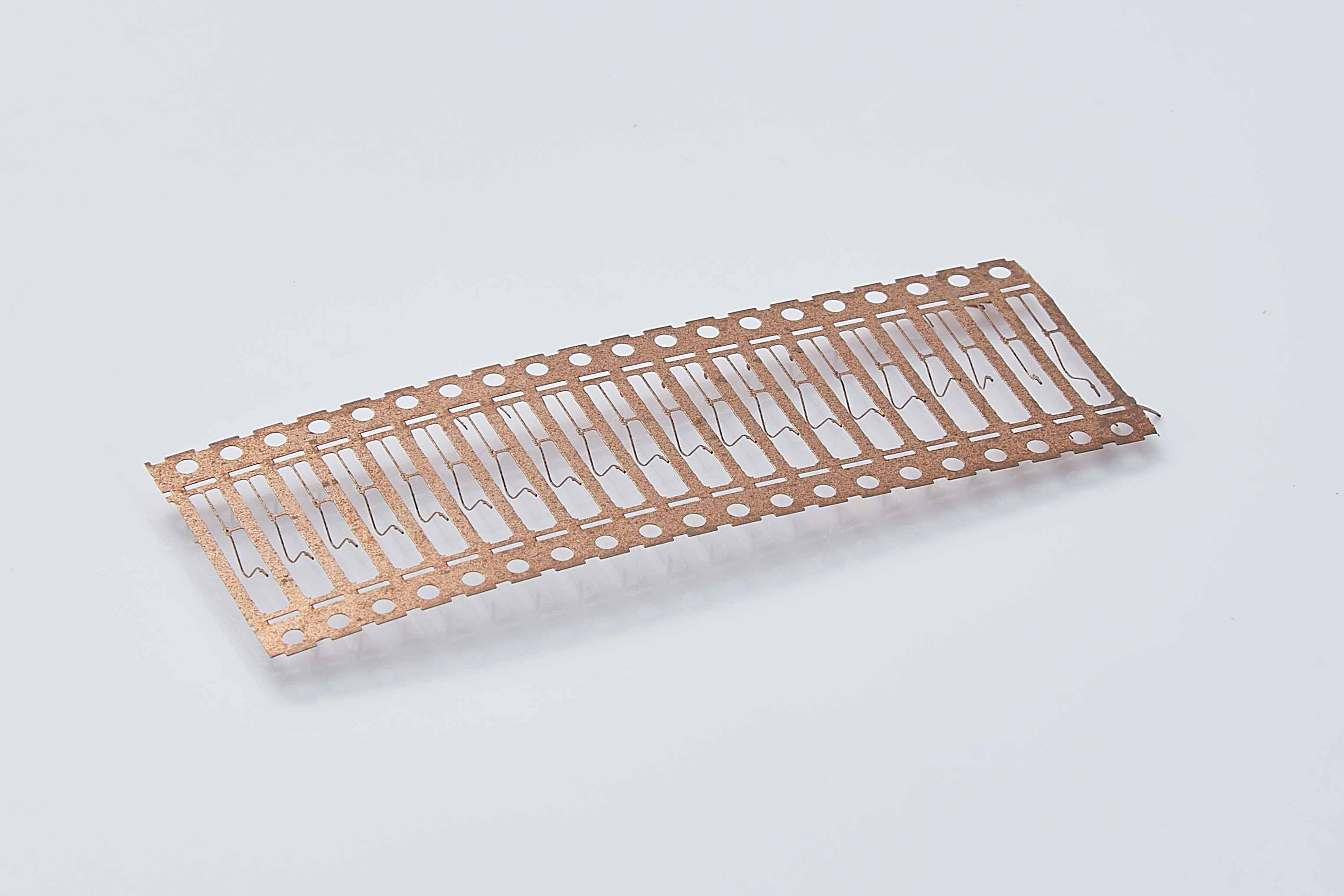

b. Material Preparation: Suitable thermoplastic resins are carefully selected based on their properties to ensure optimal performance and desired characteristics of the final part.

c. Injection: The selected plastic material is heated to a molten state and injected into the mold cavity under high pressure. The mold is then cooled rapidly to solidify the plastic.

d. Ejection: The final step involves removing the molded part from the mold cavity using ejection mechanisms such as ejector pins or air blasts.

2. Applications:

Injection molded components find extensive application in various industries, contributing to advancements and convenience in our daily lives.

a.Automotive Industry: Injection molded parts are used in automotive interiors, exterior body components, electrical systems, and engine compartments. These components offer superior strength, durability, and aesthetic appeal, ensuring safety and comfort while driving.

b.Consumer Electronics: Injection mold plastic parts are integral to electronics manufacturing, including mobile phones, computers, TV, and appliances. These parts enable precise assembly, electromagnetic shielding, and enhanced functionality, making our gadgets smaller, lighter, and more sophisticated.

c. Medical Field: Injection molding plays a crucial role in manufacturing medical devices and equipment such as syringes, IV components, surgical instruments, and drug delivery systems. The ability to produce complex, sterile, and bio compatible parts has revolutionized healthcare, improving patient care and treatment outcomes.

d.Packaging Industry: From bottles and containers to caps and closures, injection molded plastic is widely used in the packaging industry. These components offer excellent barrier properties, impact resistance, and design flexibility, ensuring product quality, freshness, and convenience for consumers.

3.Impact on daily Life:

Injection molded plastic parts have become an integral part of our daily lives, enhancing convenience, safety, and efficiency.

a.Household Items: Everyday objects such as tooth brushes, kitchen utensils, storage containers, and furniture incorporate injection molded components. These parts are lightweight, durable, and cost-effective, making them ideal for everyday use.

b.Children's Toys: Injection molding enables the production of colorful, safe, and interactive toys, promoting children's creativity, education, and entertainment. From building blocks to action figures, injection molded toys are an essential part of childhood.

c.Sports Equipment: The sports industry benefits greatly from injection molded components, providing athletes with high-performance equipment such as helmets, protective gear, and lightweight footwear. These parts enhance performance, minimize injuries, and ensure optimal comfort.

d. Environmental Considerations: Injection molding facilitates the production of eco-friendly products by using recyclable.