Why Do Tungsten Carbide Punches Outperform Steel in High-Speed Stamping?

Dec 24, 2025

In the realm of precision manufacturing, high-speed stamping stands out as a core process for mass-producing metal components with high efficiency, tight tolerances and consistent quality, widely used across automotive, electronics, aerospace and hardware industries. To unlock the full potential of this high-frequency, high-intensity machining mode, the performance of stamping die components is crucial — especially punches, the core executing part that directly determines production efficiency, product precision and overall manufacturing costs. Among all punch materials, tungsten carbide has gradually replaced traditional steel as the first choice for high-speed stamping scenarios.

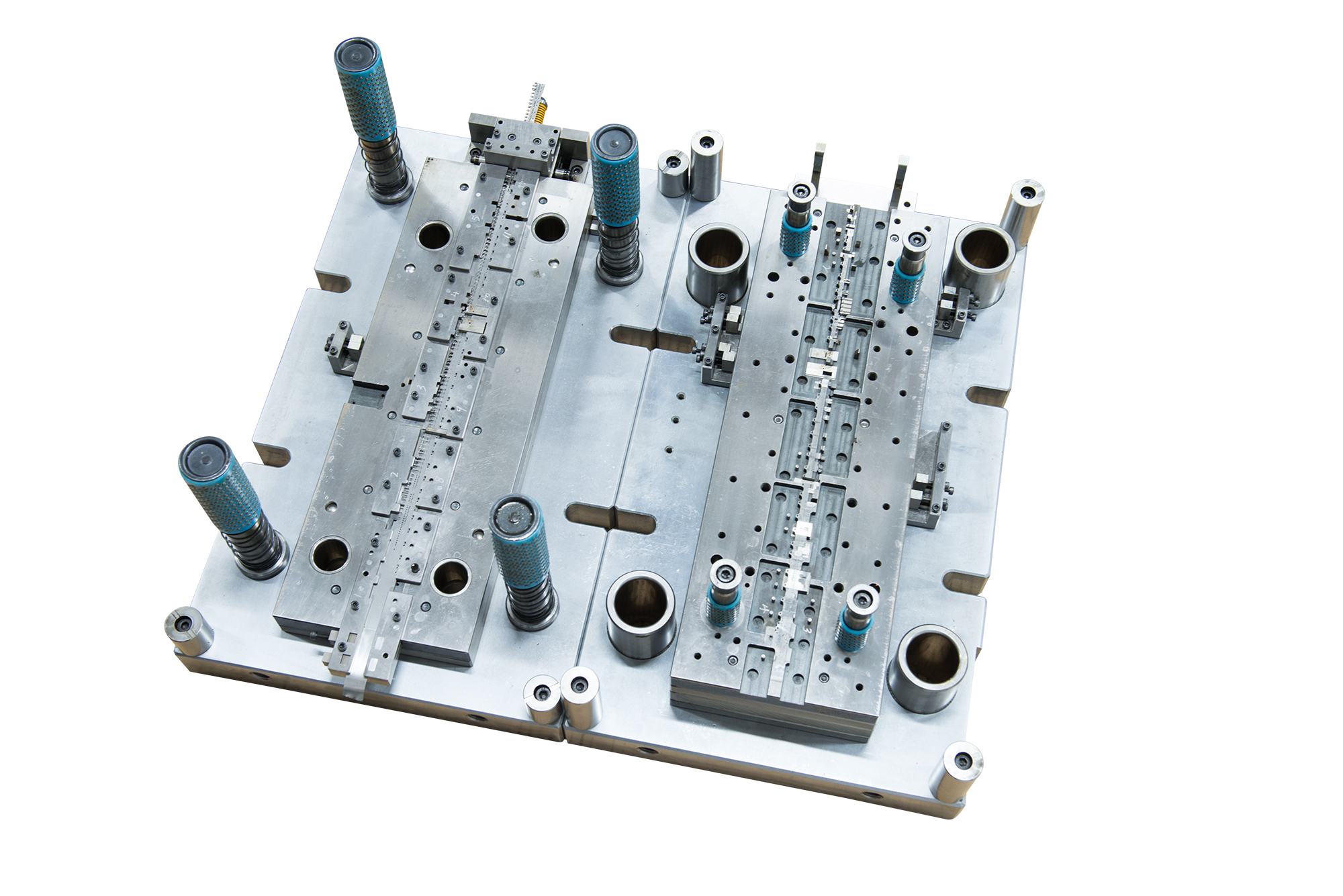

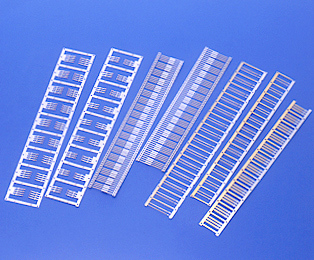

First, let’s clarify the working principle of high-speed stamping dies and the irreplaceable role of punches. High-speed stamping relies on the coordinated operation of upper and lower dies, driven by a high-speed stamping machine to realize continuous stamping, blanking, bending, forming and other processes on metal sheets or strips at a frequency of hundreds to thousands of strokes per minute. The punch, as the core active component of the upper die, directly contacts the workpiece to complete the punching or forming action in each stroke. It bears huge impact force, friction and extrusion force in high-speed, repeated operations, and is required to maintain stable precision without deformation or wear. The quality and material performance of punches not only affect the dimensional accuracy, surface finish of finished parts, but also link to die maintenance frequency, replacement cycle and production line downtime — all of which are critical to enterprise production efficiency and cost control.

When comparing the actual application effects of tungsten carbide punches and traditional steel punches in high-speed stamping, the performance gap is obvious. Traditional steel punches, such as high-speed steel, have certain hardness and toughness, and are low in cost, making them suitable for low-speed, small-batch stamping or processing low-hardness workpieces. However, in high-speed stamping scenarios, their inherent defects are exposed: poor wear resistance leads to rapid edge blunting after short-term high-frequency friction, resulting in reduced precision of finished parts and frequent replacement; low hardness makes them prone to deformation, bending or even fracture under high impact force, affecting production continuity; insufficient corrosion resistance may cause rust or wear acceleration in long-term production, further shortening service life. These problems lead to frequent downtime for die replacement, increased production costs and unstable product quality, which are difficult to meet the high-efficiency, high-precision requirements of modern high-speed stamping production.

In contrast, tungsten carbide punches show unparalleled advantages in high-speed stamping, which is the fundamental reason for their outstanding performance. The first and most prominent advantage is ultra-high hardness and wear resistance. Tungsten carbide has a hardness of HRA 85-93, far higher than traditional steel (HRC 60-65), which can withstand long-term high-frequency friction and impact in high-speed stamping without blunting or wear. This greatly extends the service life of punches, which is 10-50 times that of steel punches, significantly reducing the frequency of punch replacement and production line downtime. Second, it has excellent dimensional stability and high rigidity. Tungsten carbide has a low thermal expansion coefficient, which will not deform due to temperature rise caused by high-speed friction during continuous work, ensuring consistent precision of stamped parts and reducing product defect rates. Third, it has strong impact resistance and extrusion resistance. The dense structure of tungsten carbide enables it to bear huge impact force in high-speed stamping strokes, without bending or fracture, maintaining stable working performance for a long time. Fourth, it has good corrosion resistance, which can resist oxidation and corrosion in harsh production environments, avoiding performance degradation caused by rust and further ensuring service life and product quality. These advantages make tungsten carbide punches perfectly adapt to the high-speed, high-frequency, high-precision working conditions of modern stamping production, effectively improving production efficiency and reducing comprehensive manufacturing costs for enterprises.

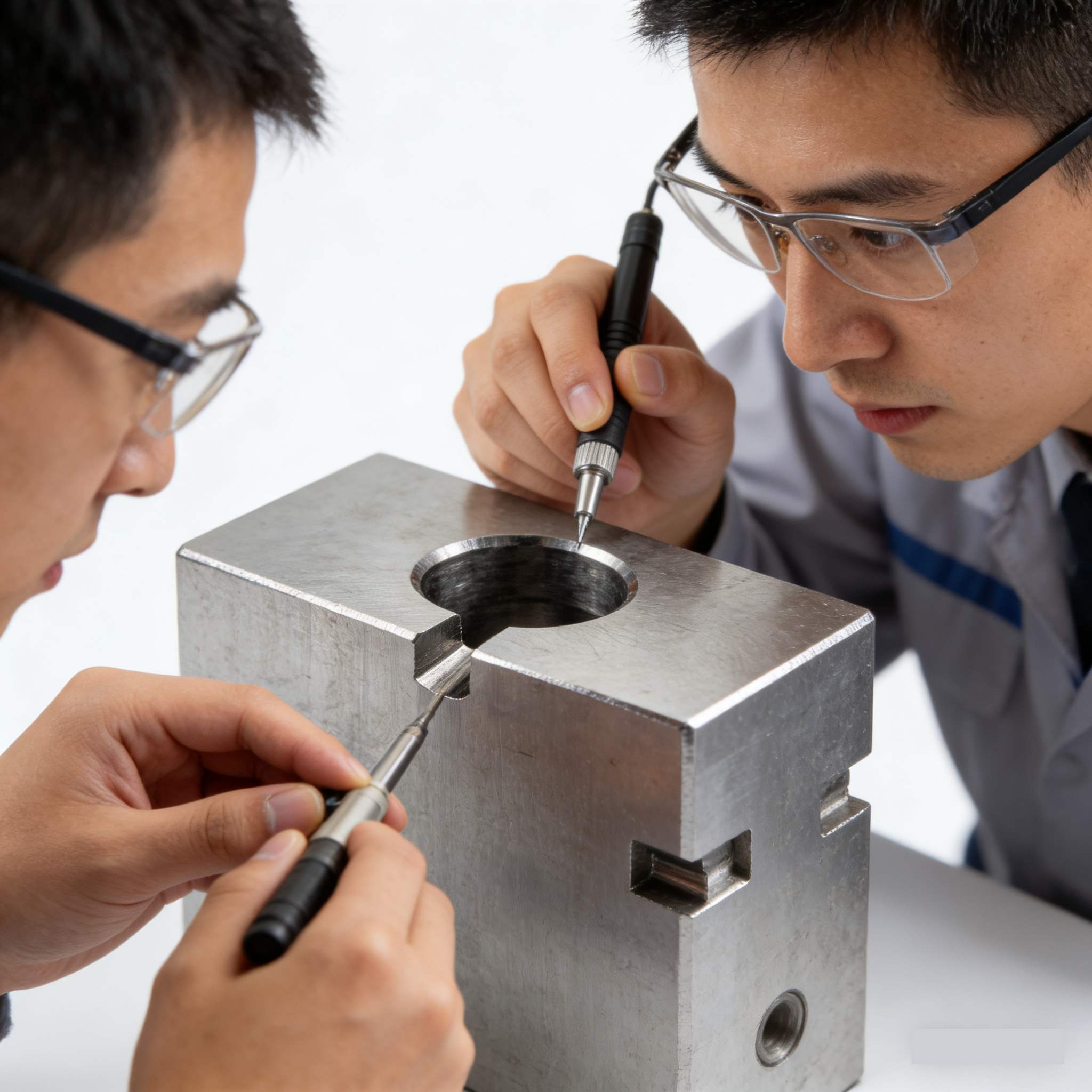

As a professional manufacturer of stamping mold components, we have obvious advantages in tungsten carbide punches, focusing on high-quality materials and rich processing experience to provide customers with reliable, high-performance products. In terms of tungsten carbide materials, we mainly adopt imported high-quality raw materials, covering a variety of grades such as fine-grain, coarse-grain and ultra-fine-grain tungsten carbide, which can be customized according to different stamping workpiece materials, thicknesses and stamping speeds to meet diverse production needs. Meanwhile, we have sufficient inventory of various tungsten carbide materials, which can shorten the production cycle and quickly respond to customers’ urgent order demands, avoiding delays caused by material shortages. In terms of processing, we have accumulated years of rich experience in tungsten carbide precision processing, mastering advanced processing technologies such as precision grinding, EDM, and surface coating. Our professional technical team can strictly control the dimensional tolerance and surface finish of punches, ensuring that each tungsten carbide punch meets the high-precision requirements of high-speed stamping. We also can provide customized processing services according to customers’ specific stamping needs, tailoring the most suitable tungsten carbide punch solutions to help customers optimize production efficiency and product quality.

In conclusion, in high-speed stamping scenarios, tungsten carbide punches outperform steel punches in wear resistance, dimensional stability, impact resistance and service life, perfectly meeting the high-efficiency, high-precision production demands of modern manufacturing. Our company relies on imported, diverse and sufficient tungsten carbide materials, as well as rich processing experience, to provide customers with high-quality tungsten carbide punches and customized solutions, helping enterprises reduce production costs, improve product quality and enhance market competitiveness. If you are looking for reliable tungsten carbide punches for high-speed stamping production, we are your trustworthy partner.