How to Reduce the Impact of Mold Components on Flash Formation in Stamped Products

Jan 07, 2026

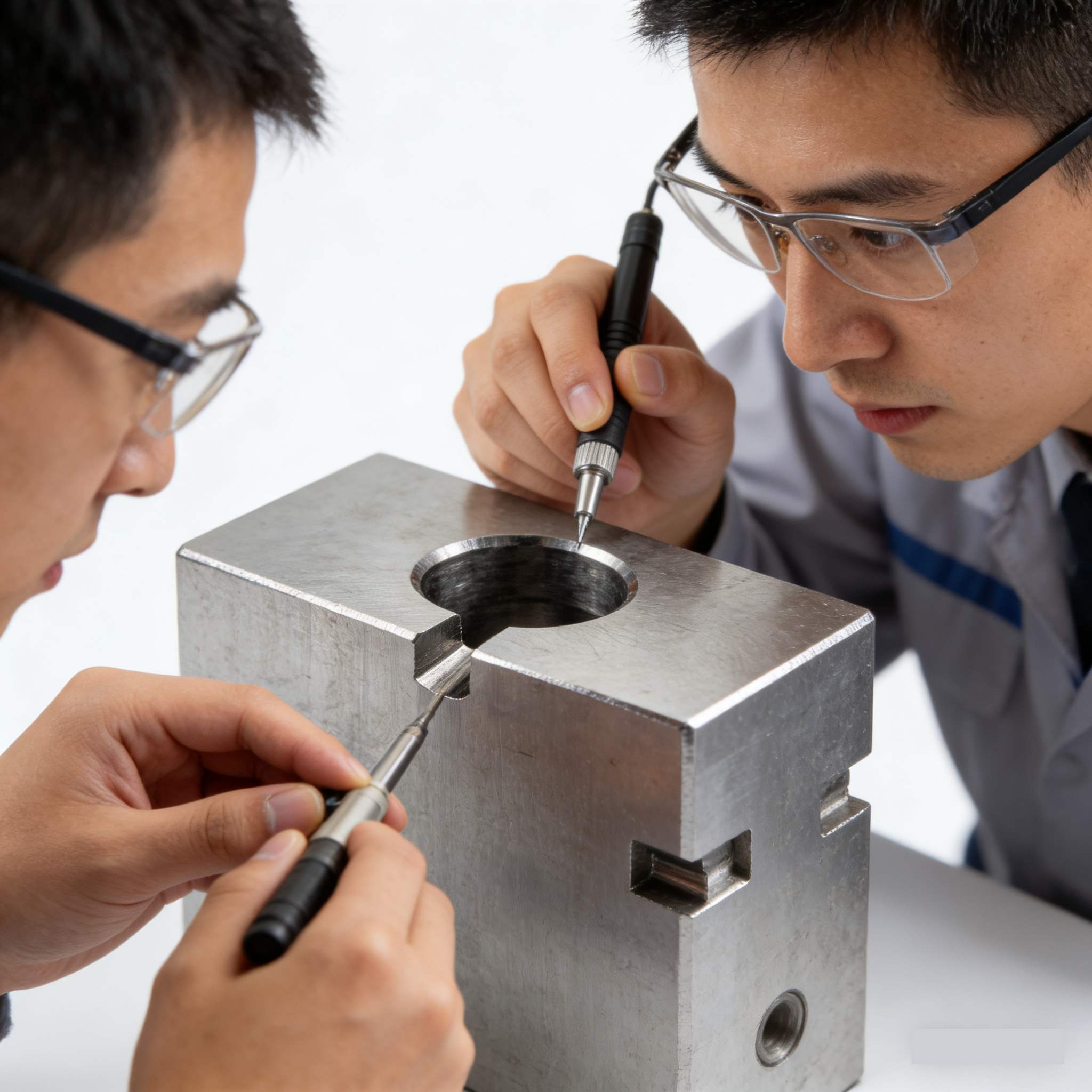

Flash is a common yet costly defect in stamping manufacturing, directly undermining product precision, aesthetic quality, and production efficiency. While factors like stamping pressure and speed play roles, mold component quality, fit, and maintenance are the core determinants of flash occurrence. For manufacturers focusing on precision stamping mold parts, targeted optimization of these components is the most direct and effective way to minimize flash-related issues.

Here are actionable strategies to reduce the impact of mold components on flash:

1. Prioritize High-Precision Components with Tight Tolerances

The foundation of flash-free stamping lies in the dimensional accuracy of core mold components. For punch and die inserts, even a 0.001mm deviation can create micro-gaps where material seeps out during stamping. Opt for inserts made from high-hardness materials like SKD11 or tungsten carbide, which resist deformation under high stamping forces and maintain tight mating tolerances over long production runs. For guide pillars and bushings, choose chrome-plated or nitride-coated options with precision-ground surfaces to ensure perfect mold alignment—misalignment is a top cause of uneven flash along the parting line. Ensure that ejector pins and sleeves have optimized clearance (0.002–0.005mm for precision applications) to eliminate leakage paths for molten or malleable material during the stamping cycle.

2. Establish a Regular Maintenance and Replacement Schedule

Wear and tear are inevitable for mold components subjected to repeated stamping impacts, but neglecting maintenance accelerates flash formation. Develop a preventive maintenance plan tailored to production volume: clean guide pillars and bushings daily to remove metal debris and re-lubricate them to reduce friction and wear; inspect punch and die edges weekly for chipping or blunting, and sharpen or replace them immediately if damage is found; replace ejector pins and springs every 50,000–100,000 cycles, depending on the material being stamped. For parting line locks and stops, calibrate clamping force monthly to ensure uniform pressure distribution, which eliminates localized gaps that lead to flash.

3. Optimize Component Assembly and Alignment

Precise assembly is just as important as component quality in preventing flash. During mold assembly, use precision alignment tools to ensure that the punch and die are perfectly centered, and that guide pillars are perpendicular to the mold base. Even a slight angular deviation can create uneven gaps along the parting line, resulting in persistent flash. For large stamping molds, use laser alignment systems to verify the parallelism of mold halves before locking them in place. Additionally, ensure that all fasteners are tightened to the recommended torque to prevent component shifting during high-pressure stamping operations.

4. Customize Component Design for Specific Stamping Materials

Different stamping materials—from thin-gauge steel to aluminum alloys—have varying levels of ductility and flow characteristics, which impact flash formation. Work with your engineering team to customize mold components for the materials you process: for soft, ductile materials, use punch and die inserts with tighter clearances and polished surfaces to minimize material adhesion; for hard, high-strength metals, opt for wear-resistant components with reinforced edges to prevent deformation. This tailored approach ensures that mold components work in harmony with the stamping material, reducing the risk of flash without compromising production speed.

Reducing the impact of mold components on flash formation is not a one-time fix—it requires a holistic approach of precision component selection, rigorous inspection, proactive maintenance, and customized design. By focusing on these strategies, manufacturers can significantly cut down on flash-related rework and waste, improve product quality, and enhance overall production efficiency. In the competitive world of precision stamping, every component detail counts—and mastering these details is the key to achieving consistent, flash-free results.

Hongyu Mould stands out as a trusted partner in solving flash-related challenges with distinct advantages tailored to precision mold manufacturing. First, we boast advanced precision machining capabilities, producing core and cavity inserts, guide pillars, and ejector components with ultra-tight tolerances, ensuring seamless mating surfaces that eliminate micro-gaps at the source.Second, we prioritize high-performance materials, utilizing tungsten carbide, heat-treated tool steel, and chrome-plated alloys that resist deformation and wear even under extreme molding pressures and temperatures, maintaining component integrity over thousands of production cycles.Third, our professional engineering team offers customized solutions—from optimized ejector clearance design to parting line clamping force calibration—addressing the unique flash pain points of each client’s mold system. Finally, we provide end-to-end technical support, including post-delivery component inspection and maintenance guidance, to ensure long-term production for our partners.Choosing Hongyu Mould means investing in reliable, high-precision mold components that elevate product quality and streamline manufacturing efficiency.